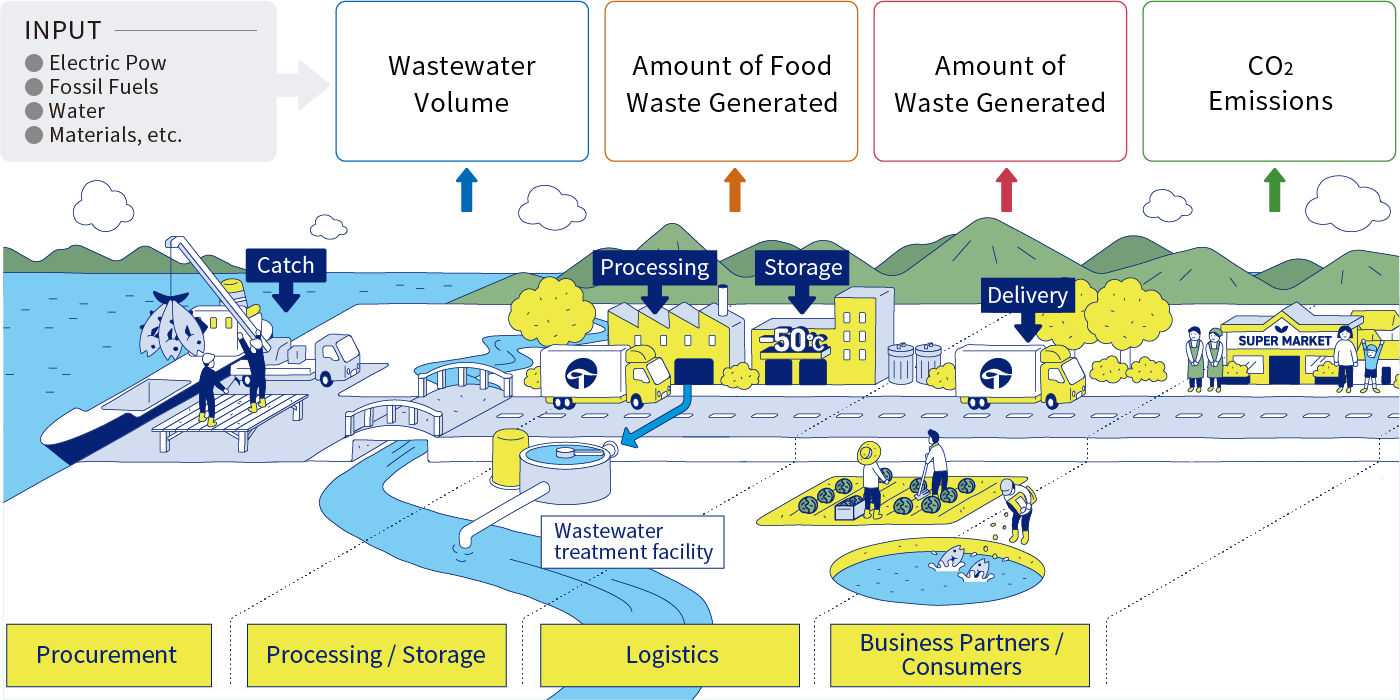

Reduction of environmental load

TOREI Group Business Activities and Environmental Impact

Since its founding, the TOREI Group has consistently handled everything from landing to processing, storage, distribution, and sales of tuna, which boasts an overwhelming domestic handling volume. We will introduce the efforts to reduce the environmental load that we are implementing in our series of business activities.

*TFL: Toyo Reizo Food & Logistics Co., Ltd.

Efforts to reduce GHG (*) emissions

Energy-saving operation of refrigerators

Ultra-low temperature refrigerators account for about 60% of the electricity used in offices. We are working to reduce electricity consumption by adjusting operations, responding to peak shifts through night shifts, appropriately defrosting, and improving the efficiency of loading and unloading methods. In addition, since 2014, we have also been gradually upgrading our refrigerators to high-efficiency, energy-saving equipment that uses natural refrigerants.

*GHG: An environmental term that stands for Greenhouse Gas, which refers to greenhouse gases.

Switching to LED lighting at offices

At our offices nationwide, we have completed the switch to LED lighting in the office areas, and by 2022, we will be converting almost all lighting, including those inside ultra-low temperature refrigerators, to LED. We are striving to further reduce energy consumption throughout the plant.

Before LED replacement

Before LED replacement After LED replacement

After LED replacement

Refrigerator management system

In the Shimizu district, which has the largest number of ultra-low-temperature refrigerators in the TOREI Group, full-time engineers manage the refrigerators on a daily basis to prevent and respond quickly to fluorocarbon leaks, and to promote energy-saving operation through appropriate equipment operation. doing. Each office appoints a person responsible for managing refrigeration and freezing equipment, and assigns a nationally qualified person as stipulated by the High Pressure Gas Safety Law according to the capacity of the refrigerator. Furthermore, we are striving to strengthen the refrigerator management system by confirming the refrigerator management status at each business site once or twice a year and providing technical guidance on maintenance and daily management, thereby achieving stable operation.

Appropriate management of water consumption and wastewater

About 50% of the waste generated by the TOREI Group is sludge discharged from wastewater treatment facilities at processing plants. Water resources are used in a variety of situations, such as thawing frozen tuna and cleaning processing plants. is managed.

Effective use of resources

Against the backdrop of global population growth and economic expansion, resource and food shortages are becoming apparent worldwide, and we may face even more serious crises in the future. As a food company involved in all stages from the production of raw materials for marine resources to product sales, we promote the reduction of food waste in the food chain and the effective use of all resources used, including food resources.

Recycling of food waste, etc.

As food-related businesses, TOREI and TFL recycle 100% of the residue generated during the tuna processing process. In addition to turning it into feed and fertilizer, we extract collagen from tuna skin and use part of the fish oil extracted from leftovers in our processed tuna products.

Efforts to reduce occurrence

In the tuna processing process, when removing inedible parts such as skin, bones, and internal organs, it is unavoidable to shave off the edible part of the meat. This meat that is shaved together is food loss. For this reason, we strictly manage yields of tuna and other products processed at our own factories, and have introduced a "saw test" to improve the skills of our workers and standardize processing standards to improve yields. increase.

Appropriate management of water consumption and wastewater

Water resources are used in a variety of situations, such as thawing frozen tuna and cleaning processing plants. In the wastewater treatment facility attached to the business site, we are managing to comply with the wastewater standards stipulated by laws and regulations, such as removing organic matter in the wastewater.