Food Safety and Security

Thoughts on food safety

As a company that provides seafood, we aim to protect and pass on Japan's fish-eating culture and contribute to the realization of a prosperous society.

We pursue safety and security for our customers throughout the entire supply chain and deliver products to them. We believe that this is TOREI quality.

In order to maintain the quality that our customers can trust, all of our employees work together to maintain and improve quality.

Quality Assurance System

As a food business, the TOREI Group works together with other group companies to ensure food safety by making the continuous supply of safe products a top priority.

The Quality Control Department at TOREI's headquarters decides on various policies and measures to implement appropriate quality assurance activities. In addition, we will play a key role in ensuring quality within the Group by monitoring quality control and supporting improvements.

- Hygiene Guidance

- At each group company's factories where ingredients and food are actually processed, a person in charge of hygiene instruction is appointed.

- Optimization of food labeling

- At our own factories and product headquarters, we have appointed "labeling managers" to ensure proper food labeling.

- Educational Guidance

- Regularly provide necessary educational training on food safety to the entire TOREI Group.

- Regular Audit

- We conduct regular audits of the contracted factories that cooperate with us in production.

Quality Control Initiatives

The TOREI Group is carrying out the following activities to maintain and improve its quality assurance capabilities throughout the food chain.

01Food Safety Management System Certification (ISO22000)

The head office and factory of Toyo Refrigerated Food & Logistics Co., Ltd. (Shimizu City, Shizuoka Prefecture), which is the TOREI Group's main production base for frozen tuna, obtained ISO22000 certification, an international standard for food safety management systems, in 2011 for its relevant departments. Now, more than 10 years after obtaining the certification, we continue to provide education to deepen each employee's understanding of the management system and ensure that it is fully implemented. In addition, our Tobishima Factory obtained the same certification in December 2024.

02Food Safety Management System Certification (FSSC22000)

In 2020, taking advantage of the opportunity to export to the United States, our Osaka branch obtained FSSC22000 certification, an international standard for Food Safety Management Systems. This certification is a management system that supplements ISO 22000 with additional requirements, and is also a standard recognized by GFSI, an organization made up of global food-related companies, so it is expected to promote greater international trade.

| ISO22000 | Registration site TOYO REIZO Co., Ltd Chubu Branch Office, Sales Division 2, Quality Control Department Toyo Refrigerated Food & Logistics Co., Ltd. Headquarters Factory, Second Refrigeration, Fourth Refrigeration Tobishima Factory (Frozen Tuna Processing Plant), Third Refrigeration Plant |

Registered Organization Toyo Refrigeration Group Shimizu Area TOYO REIZO Co., Ltd. Chubu Branch Office, Sales Division 2, Quality Control Department Toyo Refrigeration Food & Logistics Co., Ltd. Safety and Health Promotion Office, Management Department, Facility Management Department, Food Business Department, Logistics Business Department Logistics Section 1 and Section 2 |

Processing and storage of frozen fish |

| FSSC22000 | Toyo Reizo Co., Ltd. Osaka Branch | Fish processing (slices, dices, flakes) | |

| EU HACCP (Certified as a facility handling seafood products for export to the EU) |

Toyo Reizo Co., Ltd. Osaka Branch (2nd and 3rd factories) | Frozen Bigeye Tuna/Frozen Yellowfin Tuna: Loin, Block, Fillet, Diced | |

| Toyo Refrigerated Food & Logistics Co., Ltd. Headquarters Factory, Second Refrigeration, Fourth Refrigeration |

Frozen Bigeye Tuna / Frozen Yellowfin Tuna / Frozen Albacore / Frozen Atlantic Bluefin Tuna / Frozen Pacific Bluefin Tuna: Loin, Block, Fillet / Raw Material and Product Storage Warehouse (Storage of Frozen Products Manufactured by Other Companies) | ||

| Seafood processing facility HACCP certified | Sanyo Foods Co., Ltd. | Smoked salmon, smoked salmon slices, sashimi salmon, smoked scallops | |

03In-house training

- (1) We have created a "Hygiene Training Textbook" for our own factory employees and are conducting regular education on this subject.

- (2) We provide education on food labeling once a year to labeling managers and employees of the sales and production departments.

- (3) We provide all employees with education on how to prevent norovirus infection once a year.

04Internal Audit

We conduct internal audits at least once a year at our own factories and those of our group companies. We use a checklist based on our own standards to confirm whether the systems necessary to ensure food safety are being maintained.

05Audit of manufacturing subcontractors

- (1) When hiring a new outsourced production factory, we conduct a factory audit in advance.

- (2) We conduct regular audits of all our outsourced factories.

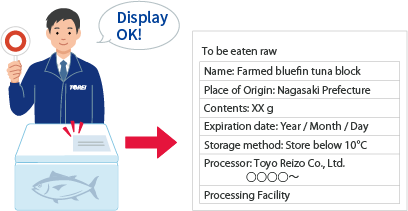

06External submission information management

We have established internal rules regarding food labeling and have put in place an internal management system to ensure that product labeling is appropriate and in accordance with the law.

- (1) Establish internal rules regarding food labeling as internal guidelines.

- (2) It is now mandatory for new products to be displayed together and for product specifications to be inspected by the Quality Control Department.

- (3) Quality control department staff are qualified as food labeling diagnosticians.

- (4) Introduction of a dedicated system for sharing product specification information within the company.

07Traceability Management

We have built a system for each product that connects product information from raw materials to the finished product. In order to accurately convey information about the origin of products and to promptly investigate any complaints, we conduct product recall training once a year for products produced in our own factories, confirm the accuracy of the tracing work and the time required, and verify the effectiveness of our traceability system.